How a Norwegian chemist defeated lead paint

Lead paint was banned. Before that, it was outcompeted by a cheap and safe alternative.

Paint is a great invention. It prevents wood from rotting and metal from rusting. This made it crucial to the industrial revolution: it strengthened steel boat hulls, engine casings, locomotives and train carriages, and iron bridges.1

Making paint requires combining two elements: a medium (the liquid), and a dry powdered pigment that’s dispersed in that medium. Suitable media, like acrylics, have the property of polymerizing over time, becoming a plastic film. Apart from giving paint its color and opacity, pigment gives physical stability to the film, making it dry to a hard surface. But without pigments the medium simply becomes a varnish, which is translucent and not nearly as tough as paint.

Before the invention of acrylic media in the middle of the twentieth century, the main option for a paint medium was linseed oil, which is made by crushing flax seeds. Linseed reacts slowly with oxygen and takes a week or longer to dry. In industrial applications demanding many coats this is a problem. Many pigments don’t speed up drying at all. Some, like carbon-based blacks, even slow it down further.

To make it durable, manufacturers added lead. Lead speeds up the drying time of paint, allowing subsequent coats to be made in quicker succession. It also reacts with the medium over long periods of time, creating a particularly stiff film through the creation of lead soaps. The pigment also lends paint antifungal, antimicrobial, and anti-corrosion properties.

This is why lead-based paint has been used in Asia and in Europe for thousands of years. Until the nineteenth century, basic lead carbonate was the only reliable white paint available. Even if you wanted a different color, it was typical to add basic lead carbonate to other paints to harness the metal’s useful properties.2

The problem is that lead is poisonous. Flakes of the paint are eaten by children, the dust of the paint enters adults’ lungs, and the heavy metal is absorbed through the skin. When ingested, the material causes cancers, chronic and acute toxicity, and reductions in IQ. But replacing it requires finding a material with similar properties.

Magnetic sand

Titanium was discovered in 1791, when a Cornish vicar called William Gregor noticed a ‘magnetic sand’ in a small stream. This was ilmenite, an ore which contains the element titanium. Gregor described in his first report that this ‘magnetic sand’ had a ‘great resemblance to gunpowder’.

Gregor tested the ore with various chemicals, mostly sulfuric acid, recording the many different colors produced over time. With one solution of sulfuric acid he got a blue color. When he used a yellow solution of sulfuric acid and acid-digested ore, then added a plate of iron, he got the hue of Port wine. Among the many colored precipitates and solutions released by Gregor’s chemical probing was a white powder.

Without knowing it, Gregor was demonstrating the fact that titanium is a transition metal: a type of element that dominates the world of pigments. These metals can exist in stable states with different numbers of electrons missing, resulting in different positive charges. In turn, this changes the way the metals absorb light energy, changing their color.

Initially, only the more exotically colored compounds of titanium were explored. In the 1830s, a deep green compound of titanium and potassium ferrocyanide was discovered by an obscure chemist, Elsner-Lampadius. The inventor of this pigment hoped it might replace Paris green, a highly toxic arsenic compound. In the 1890s, it was suggested by the chemist Joseph Barnes that impure titanium oxides (lacking any use as pigments) could be used as a fixative for wool dyes.

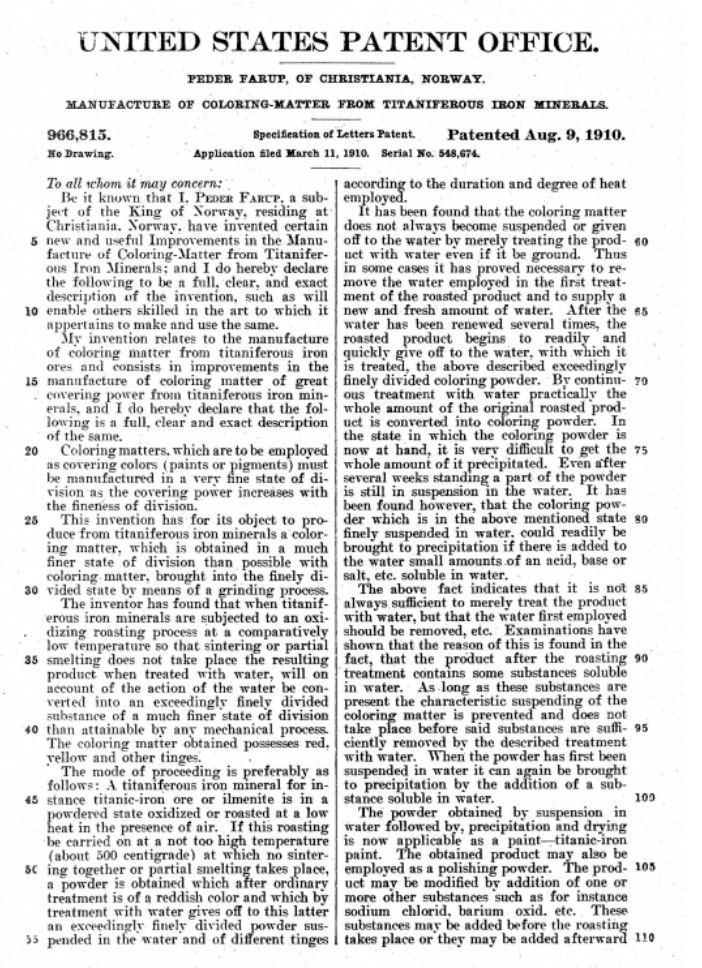

The breakthrough towards a white pigment and a substitute for lead would occur in 1909, when Peder Farup, a chemistry professor in Norway’s first technical school, tried to separate titanium from its ore. This followed a request from a government-backed committee; the new country, which had abundant iron ores of which titanium is a byproduct, was searching for uses. Farup noticed opaque red and yellow by-products: pigments.

Farup reached his next breakthrough in 1910 by mimicking the technique described by the eighteenth century Cornish vicar: digesting titanium ores with sulfuric acid. This yielded near-pure titanium dioxide, a white pigment. Though less exciting than deep green or port wine, white titanium could compete with lead white.

Mass production began in 1916. The new pigment was not perfect. It was marketed as ‘old India ivory’ – a euphemism for its off-white hue caused by iron impurities. These impurities also resulted in a gritty and unreliable pigment. Unlike lead it was neither tough nor fast-drying. But it was stable, smooth, pure, and could be made cheaply in large quantities. Most importantly, it was not poisonous.

The new titanium pigment manufacturer at Fredrikstad, Norway was bought by the US’s National Lead Company in 1927. From the 1930s onwards, titanium dioxide factories spread around the world; as production processes improved, the pigment became cheaper. In 1920, researchers at the Societé de Produits des Terres Rares, a French company, discovered the Blumenfeld process, which still involved sulfuric acid but which produces (almost) exclusively anatase titanium dioxide, a snow-white crystalline form. In the 1930s and 1940s, new processes were developed by independent laboratories in Germany and Czechoslovakia for making synthetic rutile titanium dioxide, a different crystalline configuration of the same elements but with an even greater opacity than anatase.

This made titanium increasingly competitive with lead. In 1979 the United States banned lead pigment for residential use; in 1989, the European Economic Community banned the use of lead white paint outright. But by this time lead white was already being replaced by the cheaper and safer titanium white.

Titanium dioxide was more expensive by weight than its competitors, but its cost per area covered was lower than other pigments due to its high opacity. With titanium white, the same amount of paint goes much further and fewer layers of paint are needed.

Mass production has continued driving costs down. Lead white now costs about $72 per kilogram of pigment; titanium white prices are down to $16 per kilogram.

The discovery of titanium white is a fortunate one. New pigments are incredibly rare. YInMn blue, discovered in 2009, was the first inorganic blue pigment found for almost 200 years. We still lack good alternatives to cadmium red and cadmium yellow, the highly durable primary red and yellow pigments discovered in the nineteenth century.3 Titanium white’s combination of safety, usefulness, and cost is an achievement that will likely remain unrivaled for some time to come.

Alfie Robinson is a historian.

Commercially useful stainless steel was produced only after 1913. The alternative – ‘hot-dip galvanization’, which applies liquid zinc to prevent iron from rusting – was patented only in 1836.

Zinc white was only in widespread use from the mid nineteenth century onwards, and then it was expensive to manufacture and wasn’t very opaque, making it less useful for industrial applications

Though these cadmium compounds are not toxic in themselves, elemental cadmium is, and the pigment will break down eventually. The organic pigments that would replace them fade on exposure to light and lack the strong hues of their heavy-metal counterparts.

More fun facts... White lead house paint sloughs off with weather, so the manufacturers started pitching it as "self cleaning". People painted their house with poison that sloughed off into the soil surrounding the house. We've done studies on that dirt and found that tomatoes grown in soil adjacent to old houses are often "lead based tomatoes"....with enough lead in one tomato to give the person eating that tomato an elevated blood lead level.

Thanks for sharing this essay on one aspect of the history of industrial materials.