This summer Works in Progress is hosting Invisible College, a week-long residential seminar, to give people aged 18–22 a grounding in the topics most important to us: how the world got rich, what is going wrong with science today, and the political economy of housing, urbanism, and cities. For more information and to apply, go here. Applications will close on 28th April.

In 1983, the 29-year-old Steve Jobs bought a rambling old mansion in Woodside, a quiet, wealthy little Californian town midway between San Francisco and San Jose.

The property was hardly the obvious choice for a young entrepreneur. Surrounded by six acres of encroaching forest, the dilapidated house was enormous – 30 rooms, 14 bedrooms and 13 and a half bathrooms – and was filled with odd trinkets, including a fully-functioning pipe organ.

The Apple cofounder lived there for around a decade but never actually got round to furnishing it. He would eat meals on the bare floor and sleep on a bare mattress. One girlfriend found the place so spooky she refused to live there. Eventually Jobs moved out, into a smaller, more manageable place down in Palo Alto. But the Jackling House, as it was known, would continue to haunt him, one way or another, for the rest of his life.

The house was named after the man for whom it was originally built, a fellow called Daniel C. Jackling. Don’t worry if you haven’t heard of him: he is mostly forgotten these days, but Jackling’s legacy is arguably even greater than that of the man who brought us the Mac and the iPhone.

If we have been living in Steve Jobs’ world of computers and devices for a decade or so then we have been inhabiting Jackling’s world for a century or so. Yet since Jackling was a creature of what I like to call the ‘Material World’ – the unappreciated underbelly of modern life – his contribution to our lives is enormously neglected, despite the fact that it is there in the fabric of nearly everything we touch. Jobs used to describe Jackling as a ‘copper baron’, but that was understating it, for he might better be seen as a modern-day alchemist. He was the man who transformed the job of turning rock into metal.

Up until recently it has been quite easy to forget how important copper is to the modern world. Perhaps that’s because unlike the other foundational components of civilisation like steel or concrete, copper is invariably sheathed away from view inside wiring. Yet without copper there would have been no electrical age – no second Industrial Revolution. Indeed, for a period in the late nineteenth century it looked worryingly as if the electrical era would halt before it began, because of a shortage of the red metal.

Up until the late nineteenth century, most of the world’s copper was mined and sorted more or less manually. Chunks of rock were torn away from the ground and inspected to check whether they had the tell-tale signs of copper (sometimes the green of oxidised copper, sometimes a yellow crystalline mineral known as chalcopyrite). High-grade ores with more than a few percentage points of copper were sent off for smelting and processing and the rest was left in the ground.

The problem was, by the turn of the twentieth century the most abundant ores had already been mined out. So, as the electrical age dawned, global copper production was flatlining. Even as he was inventing some of the world’s first lightbulbs and building the world’s first power stations, Thomas Edison was fretting about being able to lay his hands on enough copper to put inside them.

That brings us back to Jackling, a self-made man who came from poverty but managed to get himself trained as a mining engineer. What if, Jackling asked himself, you could extract copper not just out of those high-grade chunks (copper content of over five per cent) but also out of the other stuff too? In many mines around the world there were vast volumes of ores which looked to the untrained eye like normal rocks but contained a few percentage points of copper. They were set aside because it was simply too expensive to justify refining them. But, wondered Jackling, might there be some way of changing the calculus?

In 1904 at Bingham Canyon, just outside Salt Lake City, Utah, he answered that question in dramatic fashion. Vast quantities of explosives were deployed to blast massive chunks of low-grade ore out of the ground. Steam shovels and steam crushers were brought in to ferry and grind the ores. What was once a mountain was turned into a kind of dust, which was then mechanically and chemically processed in what became known as ‘flotation separation’: the ore dust was mixed with an oily compound and then sloshed and shaken inside large tanks, allowing copper particles to float to the surface before being smelted into solid metal.

What might sound like an arcane set of process changes turned out to be utterly revolutionary. Jackling’s ‘non-selective techniques’, as they are sometimes called, meant you could extract copper from even low-grade ores in large quantities. All of a sudden, the metal was no longer in short supply; it was plentiful. Better still, new electrolytic refining methods meant that the quality of copper being turned out by these new mega-mines was even better than the kind previously produced by older reverberatory furnaces, which roasted processed copper ores and dominated the business back in the nineteenth century, when the UK refined most of the world’s metals. That mattered because only the very purest copper could be turned into wires for generating and conducting electricity. At the very moment the world needed ultra-pure copper in large quantities, Jackling and his financiers, including the wealthy Guggenheim family, helped deliver it.

The electrical age, in other words, was not just the product of inventors and entrepreneurs like Edison, Nikola Tesla and George Westinghouse – it was thanks just as much to forgotten figures like Daniel C. Jackling. Even as Henry Ford was revolutionising mass production in Detroit, Jackling was doing much the same thing for mining, turning a small-scale industry into something enormous and vastly increasing its output in the process.

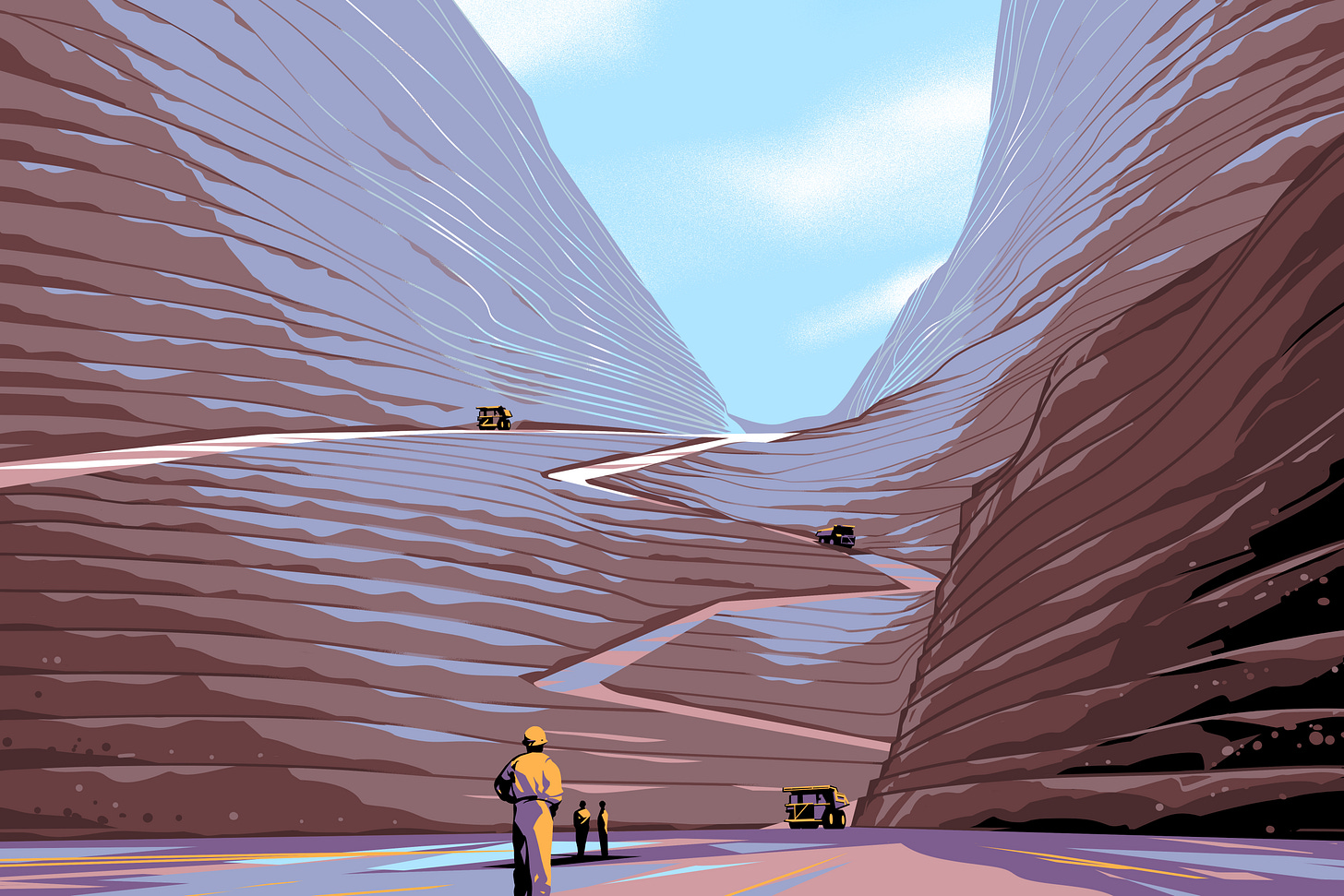

But there was a darker side to his innovation. What it meant in practice was that rather than burrowing into a mountain, following a rich seam of ore deep into the earth, miners would now essentially demolish the entire mountain to extract its metal. This was not just mass production, but ‘mass destruction’. The world got the copper it needed for the electrical era, but only thanks to the obliteration of landscapes like Bingham Canyon. Today Bingham Canyon is more than four kilometers long, two and a half kilometers wide and a kilometer deep. While it is a relatively small mine in output terms these days, it still produces staggering amounts of copper – more in a single year than the entire world produced each year before Jackling came along.

You can read the rest of the piece here.

This article first appeared in Issue 12 of Works in Progress.

Ed Conway is economics and data editor of Sky News and author of the book Material World.